What Materials are used in Composite Decking?

Composite decking is constructed from a range of different materials, each with their own strengths and advantages.

Wood

A key component of composite decking is wood. Here at Ecodek, our composite boards contain 55% hardwood fibres. These fibres are made from re-claimed beech from sawmills and are a high-quality kiln dried material. We are also registered with the Forest Stewardship Council (FSC), an organisation which offers sustainable sourcing solutions that support responsible forestry. By being a member of the FSC we are demonstrating our ongoing commitment to promoting sustainable sourcing from our UK forests.

Polyethylene

Polyethylene is the plastic component of composite decking. Ecodek boards are 45% polyethylene, which is otherwise known as recycled plastic milk bottles!

Other Materials

Other ingredients in a composite deck board include colour pigmentation, a bonding agent, and – in Ecodek boards – a high-tech ultraviolet light inhibitor package.

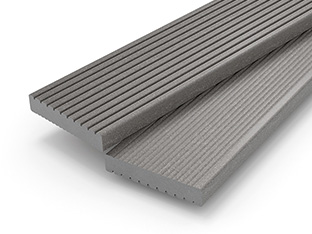

All these materials combined, create a strong, safe, sustainable, and stylish deck board that emulates real timber.

How is Composite Decking Made

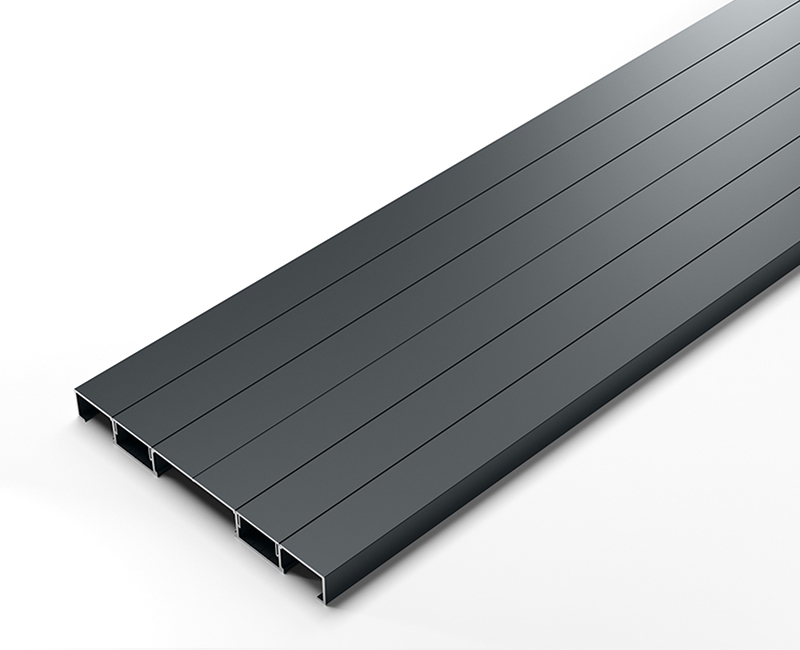

In general, composite decking is created by combining all the component materials, heating them together and forming them into boards.

Extrusion or moulded

This is the main method by which composite boards are made. Materials are combined and then either moulded into the desired shape or fed into an extrusion machine to create a board which is then cut to size.

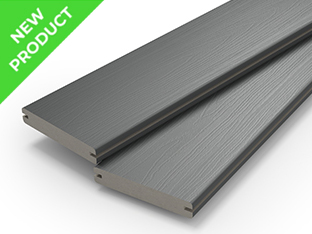

Co-Extrusion

Co-extrusion is a method by which the surface of a deck board is covered with a durable membrane. This membrane usually contains UV inhibitors, colourants, and antioxidants to conserve the materials and make the board last longer.

For further information about how we make our composite deck boards and the many benefits they offer, call our expert team today on 01978 667 840 for a no obligation chat.