Fulfilling A Decking Demand With Timber Alternative

The demand for decking materials has increased significantly during 2021, but the supply appears to be waning, according to a recent report from the Decking Network*.

The report details how despite materials still being grown and felled in places such as Scandinavia, the USA, Canada, Russia, China, Asia and Indonesia, a lack of personnel in local mills and transport systems is causing a delay in these products being exported. This has led to intensified competition between suppliers and an inevitable price increase, which is being passed on to the end consumer.

Our Managing Director, William Hogg, explains how both the increased demand and supply chain complications have been caused by the COVID-19 pandemic:

“Over the past 18 months people have been spending more time at home, for both work and pleasure. This has resulted in homeowners looking to improve their gardens or create new outdoor workspaces and, as a consequence, demand for decking has soared.

“At the same time, the pandemic has resulted in a reduced workforce, either due to employees falling ill or having to self-isolate after encountering someone who has COVID-19. This combination of increased demand and a decreased workforce has led to frustration amongst many customers waiting for their timber decking.”

William believes the answer is to buy British.

We design and manufacturer our wood composite decking boards in Wrexham, with many products carrying the Made in Britain marque. As such, we do not rely on imports from other countries to sustain our supply chain, as William continues:

“Because our products are manufactured in the UK, using recycled and sustainable materials, we can guarantee a lead time of one week for stock products and three weeks for bespoke and made-to-order decking.

“However, it is not just our location that has enabled us to maintain this steady supply. The stringent COVID-19 safety protocols and procedures we implemented at the beginning of the pandemic have enabled us to control the impact of coronavirus on our company processes. Combined, our location and rigorous health and safety practices have allowed us to continue trading, without disruption, over the past 18 months.”

We have seen a marked increase in the number of customers, both trade and consumer, turning from timber to wood composite decking, due to availability and the stability of the supply chain.

“We have received many enquiries from customers who have been let down by timber suppliers and require a viable alternative. With all the beauty of timber but the many benefits of wood polymer composite, many have been coming to Ecodek to fulfil their requirements,” adds William.

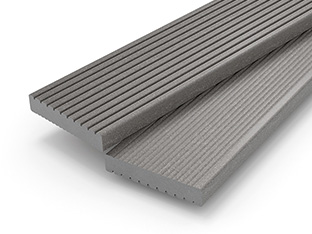

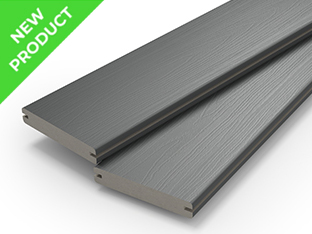

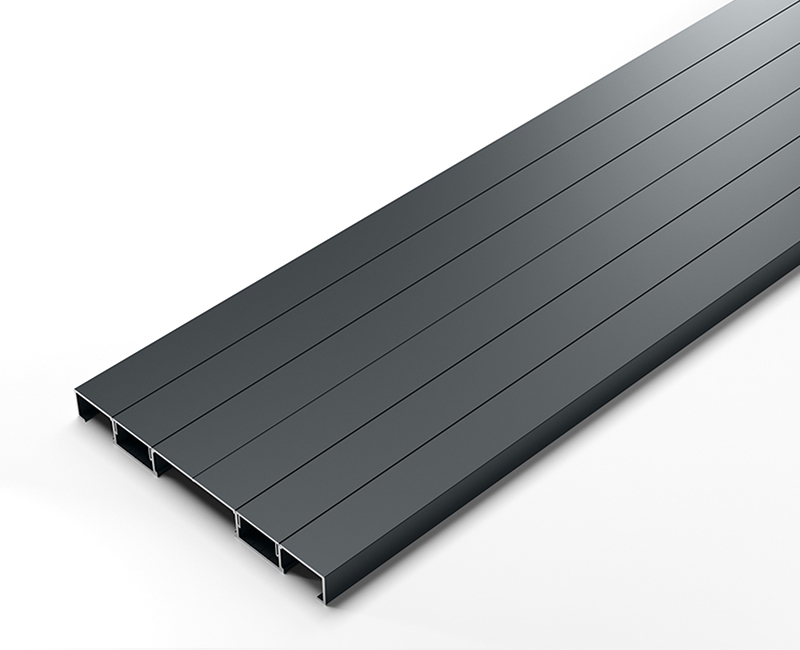

Slip resistant, low maintenance, splinter free, and rot and split resistant, our range of composite decking boards offers practical, sustainable, and attractive alternative to real timber.

“I am sure that consumers who consider locally manufactured composite as an alternative to wood will soon realise the considerable advantages it provides, in the short, medium and longer-term both with regards to its supply and environmental benefits.”