Ecodek - Championing Sustainability In All Industries

Sustainability is no longer just a buzz word used in marketing collateral to please potential customers. It is now a key consideration for many UK-based business which are concerned about the impact their manufacturing and business processes are having on the environment.

Since its foundation in 2002, Ecodek has embraced sustainability and has worked hard to ensure it is at the heart of all its business procedures. However, as a company which manufactures wood composite decking this has been a challenge, as Rob Morgan, Operations Manager at Ecodek, explains:

“By the very nature of our business – the manufacture of wood polymer composite decking solutions – becoming successfully sustainable and transparent has been challenging. However, we are achieving our environmental objectives, both in terms of our products and our manufacturing procedures, and are testimony that sustainability is attainable for any company, in any industry.”

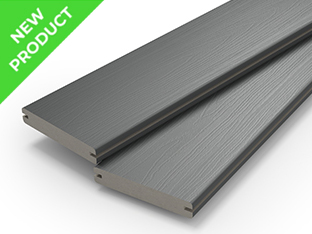

Product perfection

Regardless of what a product is made from, there are ways and means to ensure all materials used are sourced responsibly and are as sustainable as possible, as Rob continues:

“Many may think that wood composite decking is far less environmentally friendly than its timber alternative. In fact, the opposite is true.

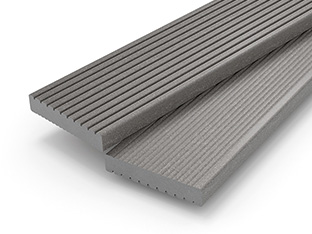

“Ecodek is manufactured using a wood polymer composite (WPC), which means it is made from a blend of sustainably sourced wood flour and recycled HDPE polymer. The material composition is approximately 55 percent wood fibres and 45 percent high-density polyethylene recycled plastic milk bottles (HDPE).

“All of the wood used in Ecodek products is Programme for the Endorsement of Forest Certification (PEFC) certified. PEFC certified material is sustainable and traceable from source, so we can guarantee its origin from the ‘forest gate’ to us.

“Finally, our finished product is 100 percent recyclable, creating a product which has a true sustainable circular lifecycle.”

Sustainable manufacturing methods

As well as ensuring product content is traceable and sustainable, it is also important to ensure the manufacturing process used to create that product is just as sustainable.

“You can work extremely hard to ensure your products are made from the most sustainable materials possible, but if your manufacturing processes are not environmentally sound, all your hard work will be undone.

“The sustainability of the production of a product is determined by its lifecycle, from cradle to customer. The manufacture of Ecodek’s wood composite decking boards is a carbon negative process, which although is a bold claim, has been verified by the BioComposites Centre of Bangor University. The Centre undertook a lifecycle assessment which considered the production of our decking boards, accounting for all significant materials, transport, energy use and packaging inputs.

“The results confirmed that the production of our deck boards had a net effect of removing carbon dioxide from the atmosphere rather than adding to it – a carbon negative process. Attaining carbon negative status can be difficult for some companies, but there are ways to minimise your effect on the environment.”

Environmental incentives

“Creating a culture of consideration amongst employees and customers is a fantastic way of improving sustainability. Internally, it reminds members of the team to be mindful of the environment whenever they are making a business decision.

“For customers, it helps to instil a sense of pride that they are doing their bit for the environment. Here at Ecodek, we introduced a ‘Buy Back’ initiative, which allows our customers to send back any unused decking or offcuts, which are then recycled back into our manufacturing process and made into new boards. In return, we offer a small payment.

“However, this exclusive scheme is only possible because our products are made from ‘clean’ plastic and untreated wood, which can both be recycled.”

A sustainable future for all

“Being a sustainable, environmentally conscious company means not resting on your laurels. We have achieved a lot over the past few years, most notably becoming a carbon negative manufacturer, however as part of the wider Epwin Group, we benefit from a wider pool of knowledge and experience, which allows us to constantly review and improve our processes.

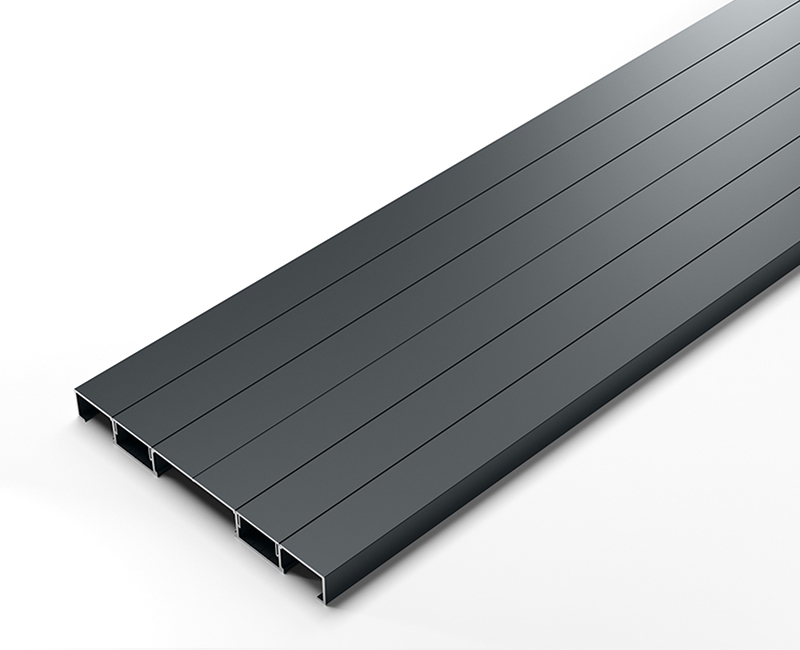

“We hope that this constant development will also benefit other industries. The flexibility of our products means they can be used for myriad applications, from outdoor shelters and bins to benches and decorative accessories, which, together with the sharing of knowledge and best practice, we hope will help other industries work towards a more sustainable future.”

Further information about Ecodek and its environmental credentials can be found at Ecodek Composite Decking – Champions of Sustainability or by calling 01978 667 840.